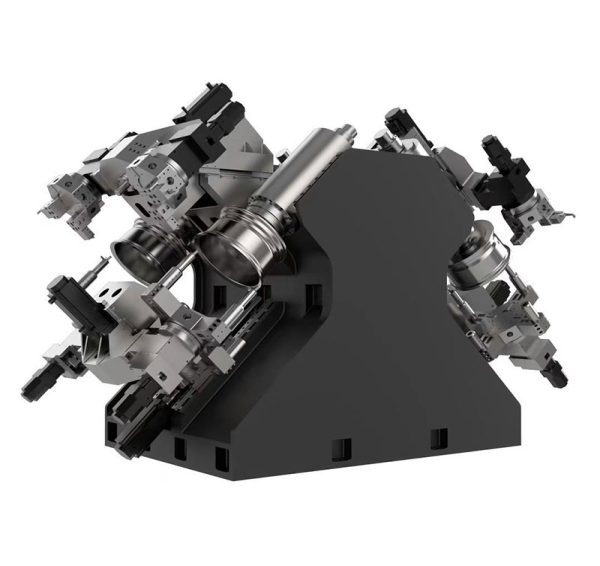

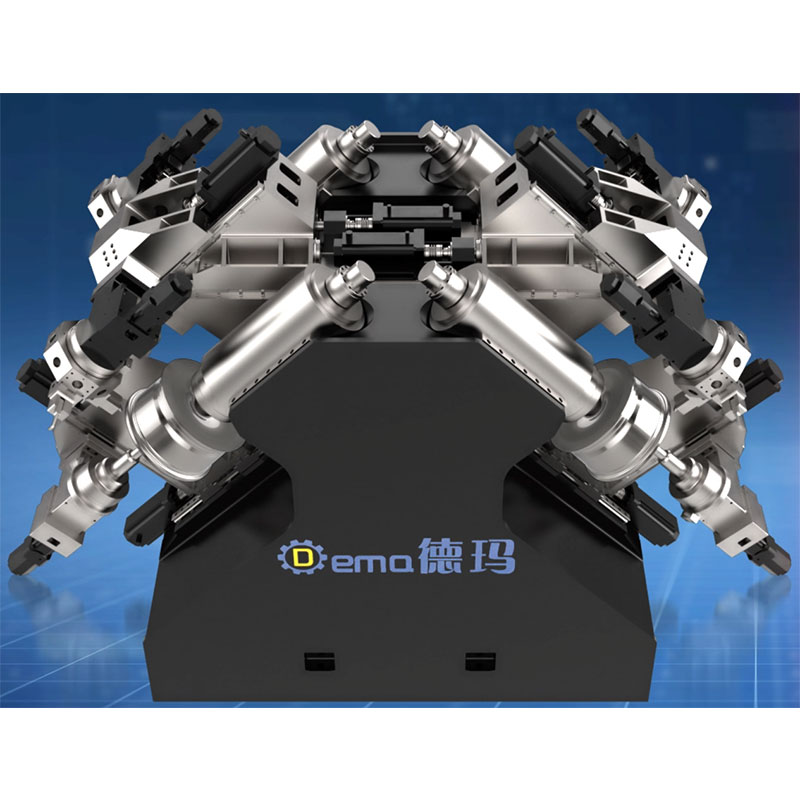

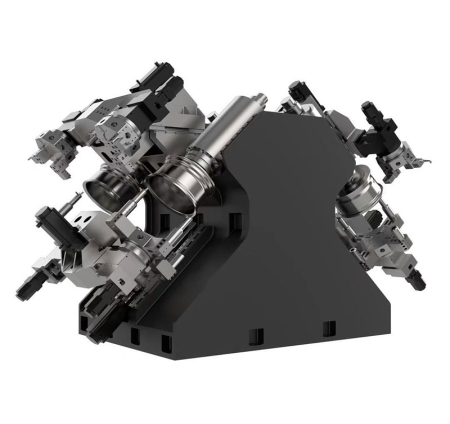

Dema four spindle lathe

1、 Main parameters of the equipment

Project | Unit | Specifications | |

Machining | Maximum machining diameter | mm | Φ700 |

Maximum cutting length | mm | 340 | |

Principal axis | Spindle end shape |

| DIN A11 |

Spindle power | kw | 37.7 | |

Maximum speed | rpm | 2400 | |

Clamping method |

| Hydraulic chuck | |

Knife tower | Knife tower capacity |

| 4 |

Tool changing speed | s | 0.2 | |

Square handle | mm | □32 | |

Circular knife handle | mm | Φ50 | |

Stroke | X1 axis travel | mm | 300 |

Z1 axis travel | mm | 335 | |

X2 axis travel | mm | 300 | |

Z2 axis travel | mm | 580 | |

Feed | X-axis rapid feed | m/min | 24 |

Z-axis rapid feed | m/min | 20 | |

Positioning accuracy | mm | ±0.01 | |

Repetitive positioning accuracy | mm | ±0.005 | |

General specifications | Electricity consumption capacity | KVA | 200 |

Air pressure | MPa | 0.5 | |

Equipment size (length × wide × High) | mm | 4600×2800×3000 | |

2、 Innovation and advantages of Dema equipment

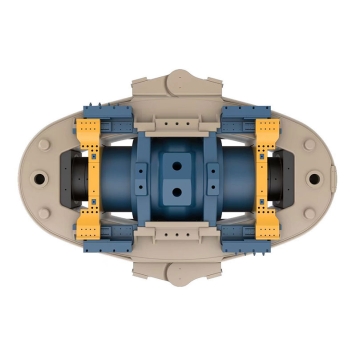

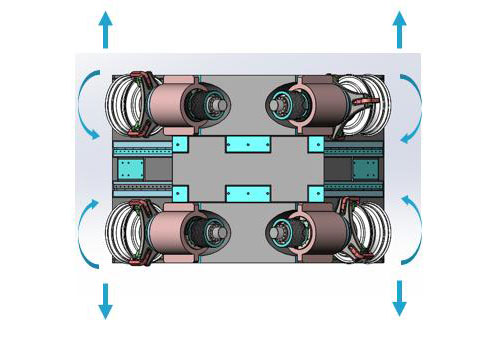

(1) Cutting force cancellation and force balance

The four main axes are symmetrically arranged on the bed, and the cutting forces generated during processing cancel out each other, ensuring a balanced force distribution on the machine tool. The rigidity of the machine tool is improved, the precision of the processed parts is improved, the vibration is reduced, and the surface smoothness level of the parts is improved.

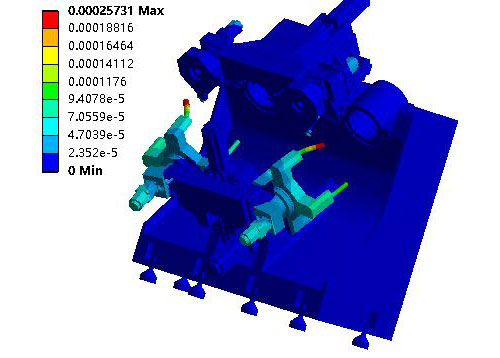

(2) Finite element analysis of the entire machine

Based on stiffness matching technology, finite element analysis of the entire machine was conducted to identify weak links in the machine tool, resulting in a significant increase in rigidity. Lightweight design of moving parts and driving along the inertial axis reduces inertial forces and moments, resulting in increased operating speed.

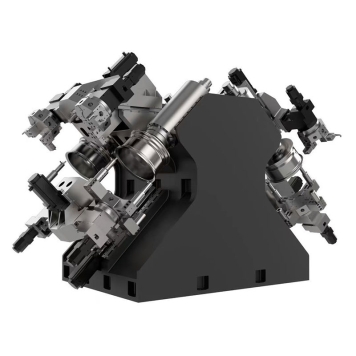

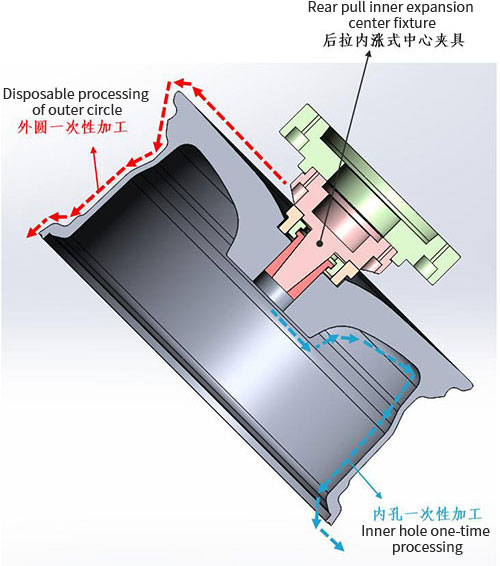

(3) Special chuck design

For car wheels, it is possible to complete the turning of both the inner and outer surfaces in one clamping process, saving energy consumption and improving machining accuracy.

3、 Configuration and performance

(1) Spindle unit

Adopting a complete set of imported Kessler electric spindles from Germany, with a power of 38kW, it has the performance advantages of high rotational accuracy, high rigidity, and low vibration, meeting the needs of long-term continuous work.

(2) System electrical appliances

Adopting Siemens or Dema's independently developed CNC system, the electrical system design and installation comply with national standards. Equipped with fault self diagnosis function, alarm function, and fault analysis function.

(3) Knife tower

Servo driven turret with fast and stable tool changing speed, hydraulic coordination with toothed clutch locking, ensuring high rigidity.

(4) Main accessories

Serial Number | Name | Allocation |

1 | Castings and machined parts | Ningbo Dema |

2 | Control system | Siemens/Dema, Germany |

3 | Principal axis | Kessler, Germany |

4 | Lead screw, wire rail | Germany Rexroth/Japan THK |

5 | Bearing | Germany FAG/Japan NSK |

6 | Pneumatic components | Japan SMC |

7 | Hydraulic device | Shanghai Qiyang |

8 | Sheet metal parts | Ningbo Dema |

9 | Electrical components | Schneider, France |

- Brand

- About Landwheels

- Product Advantages

- Development History

- Certificate of Honor

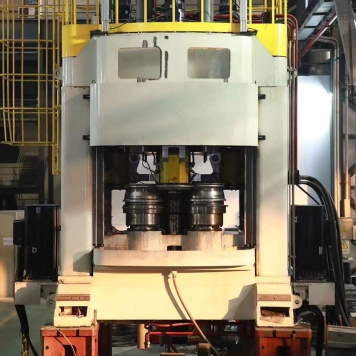

- Plant and Equipment

- Products

- Land Wheels

- Derma

- Industrial investment

- Land Wheels

- Derma

- QRcode

Technical support:和众互联 浙ICP备********号-2