Dema dual spindle machining center

1、 Main parameters of the equipment

Project | Unit | Specifications | |

Passing height below the crossbeam | mm | 465 | |

Workbench | Workbench size (length × Width) | mm | 630×1300 |

Processing scope | mm | 580×580 | |

T-slot size | mm | 100-(18×30)-5 | |

Maximum load capacity of workbench | kg | 700 | |

Stroke | X/Y/Z axis travel | mm | 580/580/178 |

Spindle nose end to workbench | mm | 440~618 | |

From the center of the spindle to the surface of the column guide rail | mm | 165 | |

Electric spindle | Spindle taper -1:10 | / | HSK 63A |

Maximum spindle speed | r/min | 18000 | |

Spindle motor | kw | 15/18.5 | |

torque | N.m | 11.8-32 | |

Feed rate | Cutting feed (X/Y/Z axis) | mm/min | 1~12000 |

Rapid feed (X/Y/Z axis) | mm/min | 32000/32000/12000 | |

Accuracy | Positioning accuracy | mm | 0.005 for the entire journey |

Repetitive positioning accuracy | mm | 0.003 for the entire journey | |

Automatic tool change system | Number of cutting tools | T | 16 |

Knife changing method | / | random | |

Maximum tool diameter | mm | Φ30 | |

Maximum tool length | mm | 180 | |

Maximum tool weight | kg | 3.5 (Tool offset load) | |

Knife handle form | HSK | HSK 63A | |

Tool change time | s | 3(T-T) | |

Other | Air pressure demand | kgf/cm² | ≥6 |

Maximum processing speed | mm/min | 12000 | |

Maximum diameter of processed workpiece | mm | Φ580 | |

Power demand | kVA | Total 55Kw - Used 37Kw | |

Machine weight (including cold box) | T | Approximately 5.6 tons | |

Floor area (long) × wide × high | mm | 2600×2590×2200 | |

2、 Innovation and advantages of Dema equipment

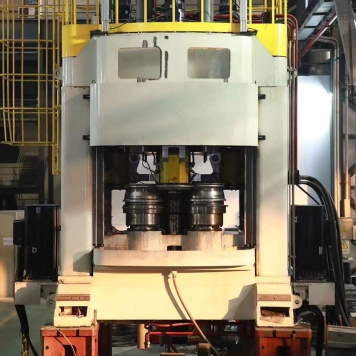

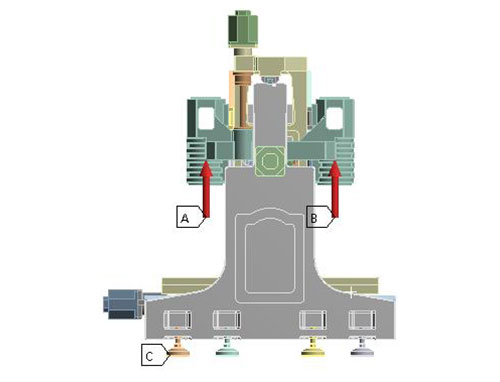

(1) Gantry frame structure, symmetrical structural layout

The bed, mountain shaped columns, and crossbeams form a gantry frame structure, which can enhance the rigidity and dynamic characteristics of the machine tool. Two main shafts are installed on the same spindle box and symmetrically arranged on both sides of the crossbeam to achieve balance between cutting torque and inertia torque.

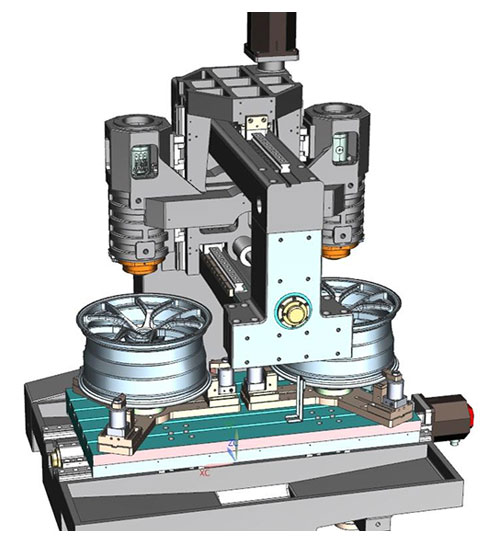

(2) Introducing dual spindle balance force

Dual spindle simultaneous machining balances the torque received during single spindle machining, reduces tool deformation, and improves accuracy. Through simulation verification, the force stiffness of the dual spindle is increased by four times.

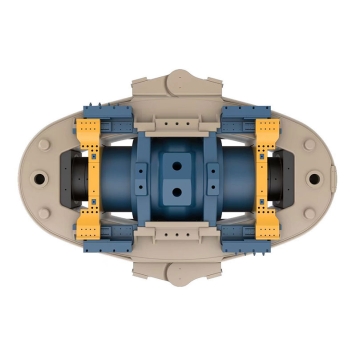

(3) Lightweight design of moving parts

By using finite element topology optimization design, weight reduction can be achieved while maintaining stiffness, which can effectively reduce inertial forces and make the motion of the machine tool easier to control.

3、 Configuration and performance

(1) Mechanical structure

The main body of the equipment is a "mountain" shape, with a large foot plate and a symmetrical spindle structure, which has advantages such as weight balance, force cancellation, and rigid feet.

(2) System electrical appliances

FANUC 0i-MF- α System package 1+AICC2 function+proflnet bus technology board, functional software, can be connected to automated robot production lines, achieving automation, unmanned, and automated production lines.

(3) Spindle unit

Equipped with HSK63-18000r/min electric spindle developed in cooperation with Dema Intelligent Machinery Co., Ltd. and Spindle Company, the spindle power is 18.5/26KW, and the maximum torque can reach 20-28Nm when operating at high speed of 11000r/min. Customers can choose the spindle model, power, and configuration according to their needs.

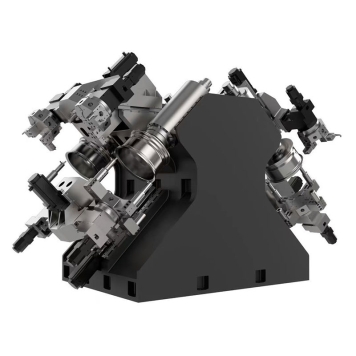

(4) Tool magazine

The matrix tool magazine HSK63-32T independently developed by Dema Intelligent Machinery Co., Ltd.

(5) Main accessories

The three-axis rail adopts THK heavy-duty high-precision grade, the three-axis screw adopts THK high-precision grade, and the three-axis screw bearing adopts NSK screw special bearing high-precision grade.

- Brand

- About Landwheels

- Product Advantages

- Development History

- Certificate of Honor

- Plant and Equipment

- Products

- Land Wheels

- Derma

- Industrial investment

- Land Wheels

- Derma

- QRcode

Technical support:和众互联 浙ICP备********号-2