Dema Four Station Five Axis Machining Center

1、 Main parameters of the equipment

| Project | Unit | Parameter |

Workpiece | Maximum workpiece diameter | mm | Φ600 |

Maximum workpiece height | mm | 390 | |

Principal axis | Tool interface |

| HSK-A63 |

Spindle power | kW | 35 | |

Maximum speed | rpm | 30000 | |

Workbench | Disc diameter | mm | Φ400 |

Allowable load capacity | kg | 500 | |

Maximum working torque | Nm | 1000 | |

Stroke | X-axis travel | mm | 850 |

Travel Y-axis | mm | 750 | |

Z-axis travel | mm | 450 | |

B-axis travel |

| 0°~+45° | |

C-axis travel |

| 360° | |

Feed rate | X-axis rapid feed | m/min | 24 |

Y-axis rapid feed | m/min | 24 | |

Z-axis rapid feed | m/min | 24 | |

B-axis speed | rpm | 50 | |

C-axis speed | rpm | 100 | |

Accuracy | Positioning accuracy | mm | 0.005 |

Repetitive positioning accuracy | mm | 0.003 | |

Power | X-axis motor | kW | 7 |

Y-axis motor | kW | 7 | |

Z-axis motor | kW | 7 | |

B-axis motor | kW | 7 | |

C-axis motor | kW | 4 | |

General specifications | Electricity consumption capacity | kVA | 220 |

Air pressure | MPa | 0.6 |

2、 Innovation and advantages of Dema equipment

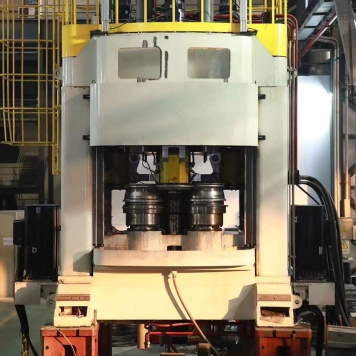

(1) Cutting force cancellation and force balance

The four main axes are symmetrically arranged on both sides of the crossbeam, and the cutting torque generated by machining cancels out each other, ensuring the balance of the machine tool's force. The rigidity of the machine tool is improved, the precision of the processed parts is improved, the vibration is reduced, and the surface smoothness level of the parts is improved.

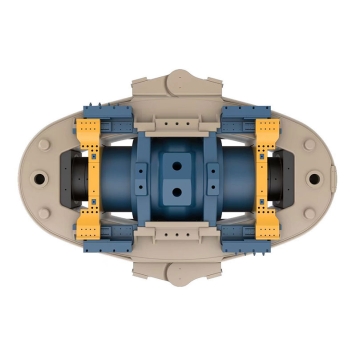

(2) Four station cradle synchronous drive

Compared with traditional cradle structures, the practical screw driven cradle device is expected to increase its load capacity by 50% under the same driving motor power, and the response speed of the new cradle within the stroke range is expected to increase by 20%. The mechanical connection between the two cradle devices only requires a set of servo drives to achieve synchronous swing of the two cradles.

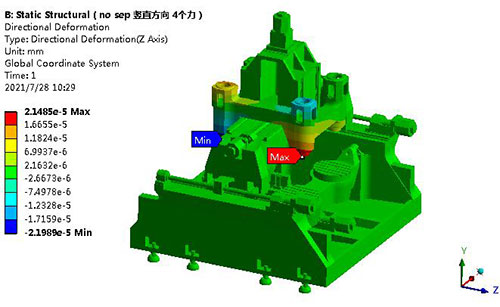

(3) Finite element simulation analysis of the entire machine

Use finite element method to optimize the entire machine and improve its static and dynamic stiffness.

3、 Configuration and performance

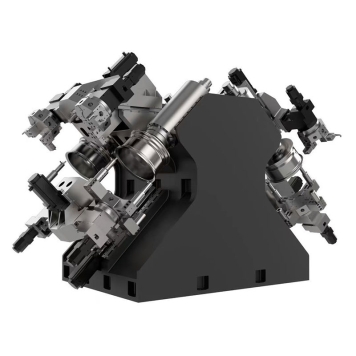

(1) Spindle unit

Adopting a complete set of imported electric spindles from Germany, with a power of 30kW and a central water outlet function, the spindle box has good vibration absorption and stiffness.

(2) System electrical appliances

Adopting Siemens or Dema's independently developed CNC system, the electrical system design and installation comply with national standards. Equipped with fault self diagnosis function, alarm function, and fault analysis function.

(3) Platform (cradle)

By using a screw drive method, a group of screws can simultaneously drive two cradles to swing simultaneously.

(4) Feed component

Driven by a high-power high-inertia servo motor, it is directly connected to the screw through a coupling. The screw bearing is a thrust angle contact ball bearing with a large contact angle, which has high axial stiffness and small starting torque.

(5) Main accessories

Serial Number | Name | Allocation |

1 | Castings and machined parts | Dema |

2 | Control system | Siemens/Dema, Germany |

3 | Principal axis | Kessler/GMN, Germany |

4 | C-axis turntable | Taiwan Shangyin |

5 | Tool magazine | Dema |

6 | Lead screw, wire rail | Germany Rexroth/Japan THK |

7 | Bearing | Germany FAG/Japan NSK |

8 | Pneumatic components | Japan SMC |

9 | Hydraulic device | Shanghai Qiyang |

10 | Sheet metal parts | Dema |

11 | Electrical components | Schneider, France |

- Brand

- About Landwheels

- Product Advantages

- Development History

- Certificate of Honor

- Plant and Equipment

- Products

- Land Wheels

- Derma

- Industrial investment

- Land Wheels

- Derma

- QRcode

Technical support:和众互联 浙ICP备********号-2