YBD26G series high-speed horizontal multi-station forging hydraulic press

1、 Basic Equipment Description

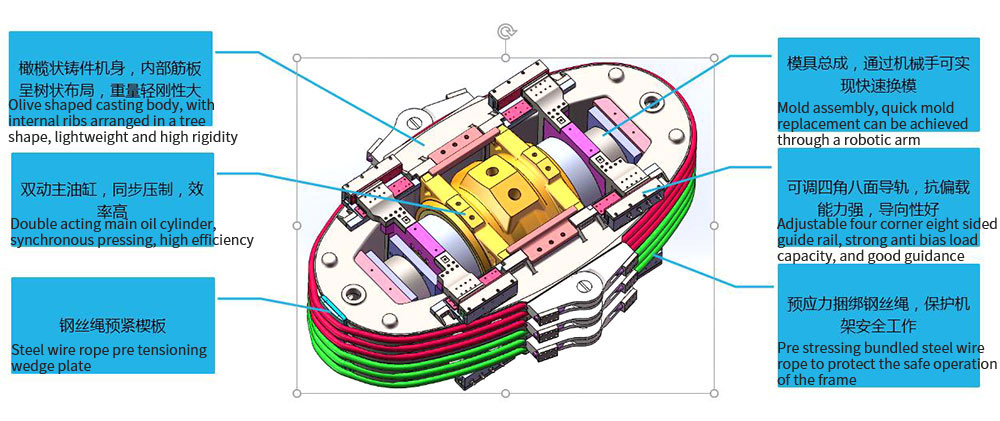

1. The main frame structure of finite element design ensures strength and stiffness.

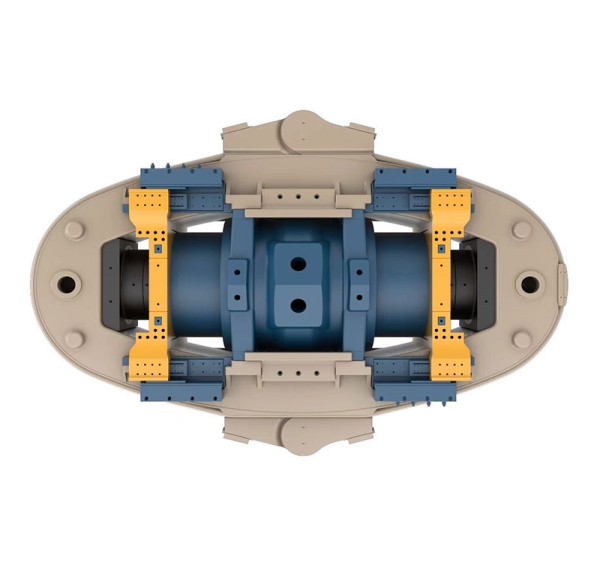

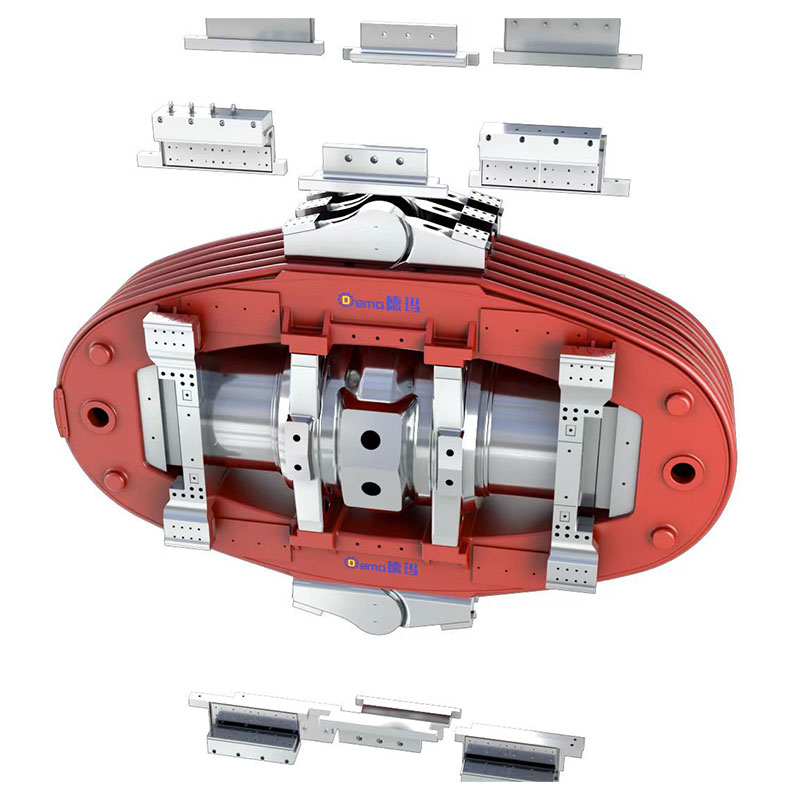

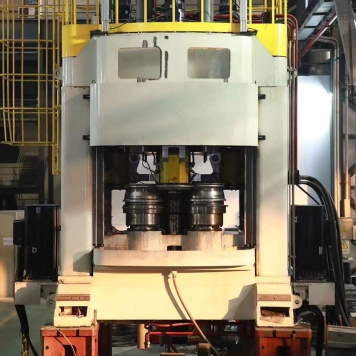

2. Horizontal dual station structure, good mechanical performance, low foundation construction cost, and high production efficiency.

3. The double safety structure composed of the frame and pre tensioned steel wire rope (belt) ensures the safety of the equipment in the event of damage or fracture in one of them.

2、 Equipment structural characteristics

3、 Equipment advantages

1. Overall finite element analysis: After analyzing the structural mechanical properties, the optimized design significantly reduces production costs compared to traditional hydraulic presses, with a production speed of about 2 pieces per minute.

2. Double acting oil cylinder horizontal layout: The cylinder body and piston rod adopt casting technology, which shortens the production cycle and is conducive to mass production. It is lightweight and reliable.

3. Olive shaped body: The body adopts an integral casting process, which can form complex cavities and has high production efficiency. The entire body casting process strictly follows the body sampling to avoid casting defects.

4、 Main technical parameters

Serial Number | Entry Name | Unit | Magnitude | ||||||

1 | Nominal force | MN | 100 | 80 | 60 | 50 | 30 | 10 | |

2 | Hydraulic system working pressure | Mpa | 25 | 25 | 25 | 25 | 25 | 25 | |

3 | Maximum working pressure of the master cylinder | Mpa | 65 | 52 | 39 | 32 | 25 | 25 | |

4 | Maximum working stroke of the master cylinder | mm | 370 | 370 | 370 | 370 | 370 | 370 | |

5 | Mold closing height | mm | 570 | 570 | 570 | 570 | 570 | 570 | |

6 | Return force | KN | 2500 | 2000 | 1800 | 1800 | 1100 | 850 | |

7 | Work rhythm | n/min | 2 | 2 | 2 | 2 | 2 | 2 | |

8 | Ejection cylinder nominal force | kN | 1000 | 1000 | 1000 | 1000 | 800 | 250 | |

9 | Ejection cylinder stroke | mm | 250 | 250 | 250 | 250 | 250 | 250 | |

10 | Ejection cylinder speed | mm/s | ≤180 | ≤180 | ≤180 | ≤180 | ≤150 | ≤100 | |

11 | Master cylinder movement speed | Quick down | mm/s | 100 | 100 | 100 | 100 | 100 | 100 |

Work | mm/s | 3~10 | 5~10 | 5~30 | 5~30 | 5~30 | 5~30 | ||

Return Trip | mm/s | 150 | 150 | 150 | 150 | 150 | 150 | ||

12 | Effective size of workbench | Around | mm | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 |

About | mm | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 | ||

5、 Main structural configuration

Number | Name | Specifications |

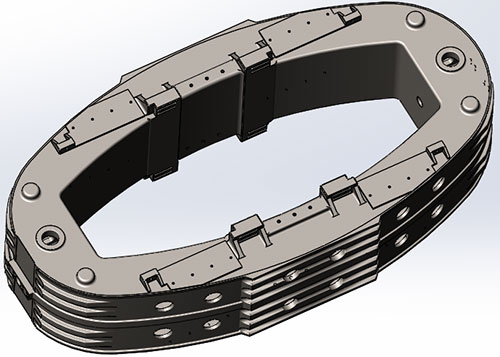

1 | Olive shaped fuselage |

|

2 | Main oil cylinder | 1400/1320-370 |

3 | Booster |

|

4 | Ejection cylinder |

|

5 | Master cylinder fixing bracket |

|

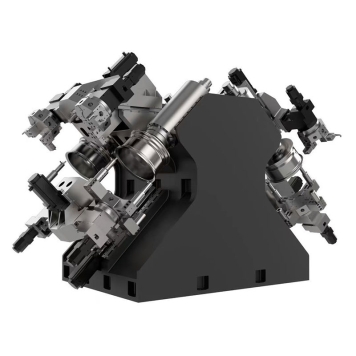

6 | "C" type detachable guide assembly |

|

7 | Slide device assembly |

|

8 | Steel wire rope and its rigging assembly |

|

9 | Copper guided wear-resistant block |

|

10 | Insulation pad | Ø1200 |

11 | Dry oil automatic lubrication system | SDRB-25 |

| Hydraulic system configuration | |

● Main pump and control pump system | ● Liquid filling system |

| ● Oil tank device | ● Pump station foundation cover plate and supporting structural components |

| ● Cooling and filtering circulation system | ● Pump set adjustment pad |

| ● Integrated valve block control device | ● Complete set of pipes and flanges |

| Electrical system configuration | |

| ● PLC programmable controller | ● Displacement sensors |

| ● Detection system | ● Pressure sensors |

● Control software system | ● Control transformer |

- Brand

- About Landwheels

- Product Advantages

- Development History

- Certificate of Honor

- Plant and Equipment

- Products

- Land Wheels

- Derma

- Industrial investment

- Land Wheels

- Derma

- QRcode

Technical support:和众互联 浙ICP备********号-2