Part 1 Basic Knowledge of Wheel Hubs

Wheels, as the main load-bearing components of the entire vehicle, are the most important safety components that affect the overall performance of the vehicle. It not only needs to withstand the vertical self weight load of the vehicle itself in static state, but also needs to withstand the irregular stress generated by various dynamic loads from different directions during vehicle driving, such as starting, braking, turning, stone impact, and uneven road surface. As the most important wheel hub component, it can be said to be one of the main symbols for measuring the quality and grade of the entire vehicle. So, how is a wheel hub that emphasizes safety, excellence, aesthetics, and practicality produced?

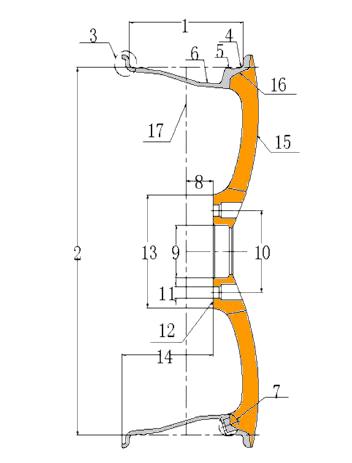

1、 The basic structure of the wheel hub

1. Rim width |

|

2. Nominal diameter of wheel rim | |

3. Rim | |

4. Bead seat | |

5. Convex peak | |

6. Trough bottom | |

7. Valve hole | |

8. Offset ET | |

9. Center hole C \ B | |

10. Bolt hole pitch diameter PCD | |

11. Bolt hole diameter | |

12. Spoke mounting surface | |

13. Installation surface diameter | |

14. Posterior distance | |

115. Spokes | |

16. Wheel rim | |

17. Rim centerline |

1. Wheel rim: The part of the wheel that supports the tire during assembly.

2. Spoke: The wheel part that is installed and connected to the axle hub, supporting the wheel rim.

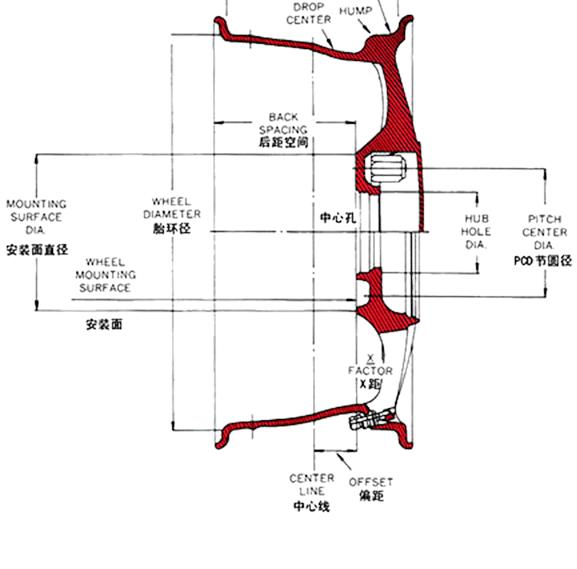

3. Offset: The distance between the center surface of the wheel rim and the mounting surface of the spoke. There are positive offset, zero offset, and negative offset.

4. Rim: The part of the wheel rim that maintains and supports the direction of the tire.

5. Bead seat: The part of the wheel rim that is in contact with the tire rim and supports the radial direction of the tire.

6. Bottom groove: For the convenience of tire installation and removal, a certain depth and width of pits are left on the wheel rim.

7. Valve hole: The hole for installing the tire valve.

Part 2 Key parameters for modifying wheel hubs

1、 Main parameters for modifying wheel hubs

1. PCD: The installation parameters must be consistent. German cars generally have 5 holes, such as BENZ which has 5 holes × 112mm, while BMW mostly has 5 × 120mm. And the common models in China are 4/5 × 100/114.3mm. Off road vehicles are mostly 6 × 139.7mm, a large displacement of 5 holes is more reasonable, for example, the Toyota 4700 is 5 × 150.

2. Offset/ET: The smaller the offset, the larger the wheelbase. After upgrading the wheel rim, the wheelbase will change according to the width of the wheel rim. If the wheel rim is upgraded, it is necessary to consider whether the wheel hub will interfere with the inner shock absorber and the outer mudguard (this knowledge will be explained later in the diagram). The appropriate offset size can ensure that the wheel hub will not interfere, for example, the original Audi A8 model 16 × 7.5 is ET38, 18 × 8 is ET35, 19 × 8.5 is ET30.

3. X-FACTOR: Will it touch the brake disc? Generally, it is required to be>27mm.

4. Center hole (HUB HOLE/CB): It varies from car to car, for example, BENZ is generally 66.6mm, BMW is generally 72.6mm. If the center hole of the wheel hub is too large, be sure to use a center hole collar, otherwise the car will shake when driving at high speed.

Chapter 3 Advantages of Wheel Hub and Tire Upgrade and Modification

As a very important component of a car, four tires can affect the comfort and handling performance of a car by touching the ground with an area about the size of four postcards. Tires are undoubtedly the most important consumable material in a car (except for gasoline). Overall, the wheels and tires installed on the new car were selected by the factory after repeated road tests. Why do we still need to upgrade and replace them?

Because the vast majority of original factory equipment is equipped with small-sized aluminum alloy wheels or even steel wheels for cost control purposes; In terms of tires, considering the best performance of the vehicle, it is difficult to achieve both comfort and wear resistance. For the sake of balance, the original factory equipped tires must have a certain degree of compromise in terms of performance, noise, wear resistance, and comfort. Therefore, upgrading the wheels and tires is the first step in improving vehicle performance and aesthetics.

1、 Why is it trendy to play with big wheels?

The wheel hub is the "shoe" of a car. Installing large-sized wheels can make your car look beautiful and luxurious. On the premise of keeping the wheel diameter unchanged, increasing the diameter of the wheel hub and using flat tires will make your vehicle visually stunning.

The vibration absorbers of high-end cars are all controlled by computers, but to achieve a smoother and more comfortable experience, they must be equipped with large-sized wheels and flat tires. This not only allows for the free elasticity of the customer's tires, but also allows for personal adjustment.

The wheel hub size is increased and widened, and flat tires are installed, greatly increasing the contact area of the wheels, greatly improving the grip and braking performance of your vehicle while driving, making your driving safer.

The combination of large-sized wheels and flat tires will improve the cornering performance of your vehicle and satisfy your driving pleasure.

Advantages of assembling flat tires:

● High safety: The widened tread, large contact area, and enhanced grip result in high safety

● Better handling performance: reduces slip and drift, making handling more flexible

● Smooth braking: wider tread, larger friction area, and shorter braking distance

● Smooth braking: wider tread, larger friction area, and shorter braking distance

● Smoother driving: low flatness ratio, reduces body inclination during turns

● Personalized and bold: The wide tread and enlarged diameter electroplated aluminum wheels highlight a noble sense of value

- Brand

- About Landwheels

- Product Advantages

- Development History

- Certificate of Honor

- Plant and Equipment

- Products

- Land Wheels

- Derma

- Industrial investment

- Land Wheels

- Derma

- QRcode

Technical support:和众互联 浙ICP备********号-2